China Custom Supply Vacuum Circuit Breaker Company For Sale Price

The backbone of modern electrical infrastructure is the ability to control and protect the flow of electricity. Vacuum circuit breakers are critical components in this infrastructure, designed to manage and safeguard electrical circuits against faults and overloads. These devices are chosen for their efficiency, reliability, and the unique properties of vacuum as an insulating and arc-quenching medium.

A vacuum circuit breaker operates on the principle of using a vacuum as the dielectric medium to extinguish the arc created when the circuit is interrupted. The vacuum environment is crucial because it significantly reduces the pressure, pilot to a rapid cooling effect on the arc. This rapid cooling and the absence of particles to sustain the arc contribute to the quick extinguishing of the electrical arc, thus protecting the circuit from damage.

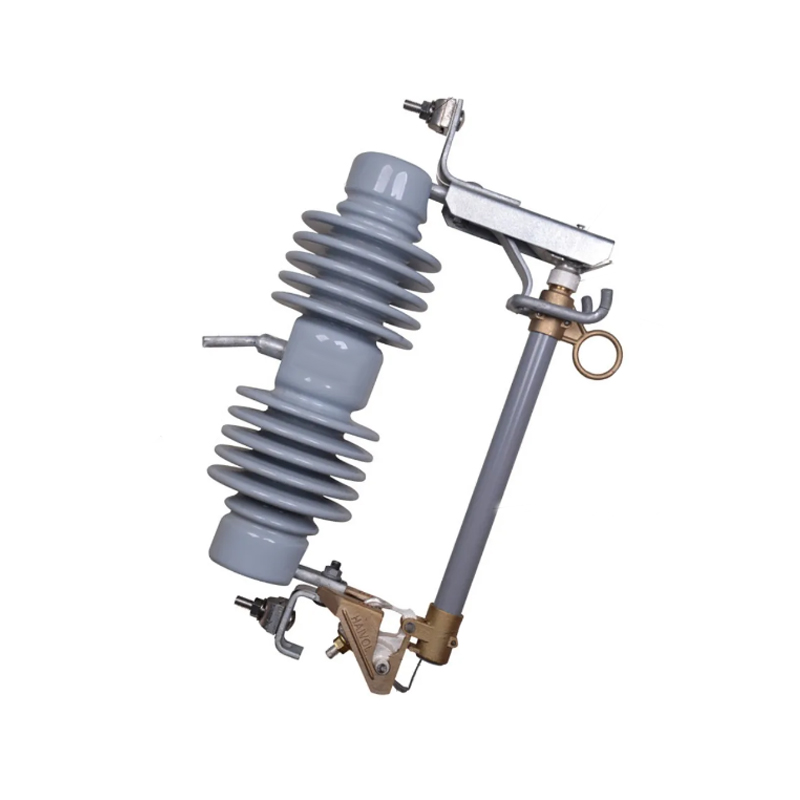

Components of a Vacuum Circuit Breaker

1. Contact Assembly: The contacts are the heart of the breaker, where the electrical connection is made or broken. They are designed to withstand high temperatures and pressures during operation.

2. Vacuum Interrupter: This is the core component where the vacuum is maintained. It houses the contact assembly and ensures the arc is extinguished when the contacts separate.

3. Actuator Mechanism: This mechanism is responsible for the opening and closing of the contacts. It can be manual, spring, or motor-operated, depending on the application.

4. Arc Chute: Although the vacuum aids in arc suppression, the arc chute is designed to direct and cool any residual arc, ensuring complete interruption.

5. Insulating Housing: The housing provides electrical insulation and mechanical support to the internal components, ensuring safety and structural integrity.

Advantages of Vacuum Circuit Breakers

1. Long Service Life: The absence of moving parts in contact with air or oil means less wear and tear, pilot to a longer service life.

2. Low Maintenance: Due to the sealed vacuum environment, these breakers require small maintenance, reducing operational costs.

3. High Dielectric Strength: The vacuum provides dielectric strength, allowing for smaller and lighter designs compared to other types of circuit breakers.

4. Fast Operation: The rapid arc-quenching capability of vacuum breakers allows for quick operation, which is crucial during fault conditions.

5. Environmental Compatibility: Vacuum circuit breakers do not use environmentally harmful substances like SF6 gas, making them an eco-friendly choice.

Applications of Vacuum Circuit Breakers

1. Power Distribution: In industrial, commercial, and residential power distribution systems, vacuum breakers provide reliable protection against short circuits and overloads.

2. Substations: They are used in substations to protect transformers, generators, and other critical equipment from electrical faults.

3. Railway Systems: Vacuum breakers are used in railway traction systems for their reliability and fast operation, ensuring safe and efficient train operations.

4. Renewable Energy: In wind and solar power systems, vacuum circuit breakers protect the inverters and other components from electrical faults.

While vacuum circuit breakers offer numerous advantages, they also face challenges such as the need for higher voltage ratings and the development of smart grid technologies. Future developments may include the integration of sensors and IoT technologies for real-time monitoring and predictive maintenance.

Vacuum circuit breakers are a testament to the evolution of electrical protection technology. Their unique ability to extinguish arcs in a vacuum environment has made them a preferred choice for various applications.

English

English русский

русский عربى

عربى