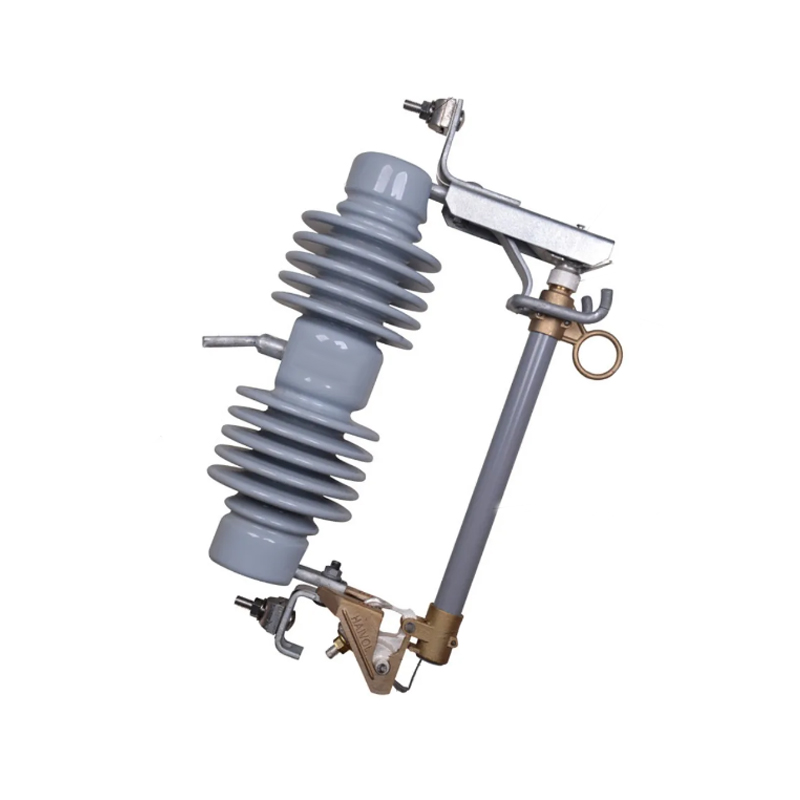

In the realm of electrical engineering, the development of reliable and efficient switching devices is paramount. Vacuum Interrupters, also known as Vacuum Contactors or Vacuum Switchgear, have emerged as a cornerstone in the field of electrical power distribution and control.

The journey of Vacuum Interrupters began in the mid-20th century when engineers sought to improve upon the existing arc suppression techniques in electrical switching. Traditional oil-filled and air-break switches were prone to maintenance issues and inefficiencies. The introduction of vacuum as an insulating and arc-quenching medium marked a significant leap forward.

Vacuum Interrupters operate on the principle of utilizing a vacuum to extinguish electrical arcs. The vacuum environment is ideal for this purpose due to its high dielectric strength and the absence of particles that could otherwise sustain an arc. Over the years, the design and materials used in Vacuum Interrupters have been refined, pilot to increased reliability and performance.

Importance of Vacuum Interrupters:

1. Reliability: One of the key advantages of Vacuum Interrupters is their reliability. The vacuum environment ensures that the contacts do not oxidize, which is a common issue with other types of switches. This results in a longer service life and reduced maintenance requirements.

2. Safety: Vacuum Contactors are inherently safer than their counterparts that use oil or air as an insulating medium. There is no risk of fire or explosion associated with the use of vacuum, making them ideal for use in hazardous environments.

3. Environmental Friendliness: Unlike oil-filled switches, Vacuum Switchgear does not pose a risk to the environment. There is no risk of oil leakage, which can be harmful to both humans and the ecosystem.

4. Compact Design: Vacuum Interrupters are compact and lightweight compared to traditional switches. This makes them ideal for applications where space is at a premium.

5. Low Operating Costs: Due to their low maintenance requirements and long service life, Vacuum Interrupters offer significant cost savings over time.

6. High Dielectric Strength: The vacuum environment provides a high dielectric strength, which allows for the safe interruption of high voltage currents.

7. Fast Operation: Vacuum Contactors can operate at high speeds, making them suitable for applications that require quick switching.

8. Wide Range of Applications: Vacuum Switchgear is used in a variety of applications, from residential and commercial buildings to industrial facilities and power generation plants.

With the advent of smart grid technology and the increasing demand for energy efficiency, Vacuum Interrupters have continued to evolve. Modern Vacuum Interrupters incorporate advanced materials and designs that enhance their performance and adaptability to different voltage levels and current ratings.

The integration of Vacuum Interrupters with smart grid technology has opened up new possibilities for energy management. These devices can now be remotely monitored and controlled, allowing for more efficient power distribution and load management.

As the world moves towards more sustainable and efficient energy systems, the role of Vacuum Interrupters is set to expand. Research and development in this field are focused on further improving the performance, miniaturization, and integration capabilities of these devices.

In conclusion, Vacuum Interrupters, or Vacuum Contactors and Vacuum Switchgear, have come a long way since their inception. They have proven to be indispensable in modern electrical systems, offering a combination of reliability, safety, and environmental benefits.

English

English русский

русский عربى

عربى