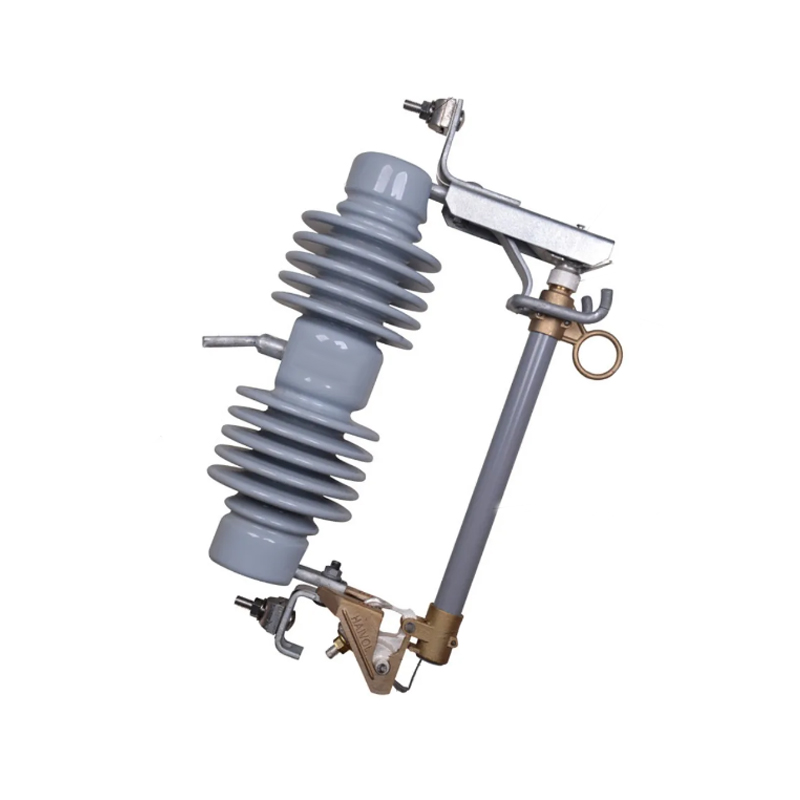

Supply Custom Distribution Board Cabinet Producer For Sale

Distribution board cabinets are essential components in electrical systems, providing a centralized point for the control and distribution of electrical power. These cabinets are designed to ensure safety, efficiency, and organization in the routing of electrical currents.

Distribution board cabinets serve as the backbone of electrical systems in both residential and commercial settings. They are responsible for the safe and efficient distribution of electricity from the main power source to various circuits and outlets. By centralizing the control of electrical power, these cabinets help to prevent overloads, reduce the risk of electrical fires, and facilitate easier maintenance and troubleshooting.

The design of a distribution board cabinet is crucial for its performance and safety. Several factors are taken into account during the design process:

Material Selection: Cabinets are typically made from materials that are resistant to corrosion and have high electrical insulation properties, such as galvanized steel or non-combustible composites.

Size and Capacity: The size of the cabinet must be appropriate for the number of circuits it needs to manage. It should have enough space for future expansion as well.

Modularity: Many cabinets are designed with modular components, allowing for easy customization and upgrades as electrical needs change.

Safety Features: Incorporating features such as circuit breakers, residual-current devices (RCDs), and surge protection is essential for preventing electrical accidents.

Accessibility: The design should allow for easy access to the components for maintenance and inspection, often with removable doors and clear labeling.

Distribution board cabinets are used in a wide range of applications, including:

Residential Buildings: In homes, they manage the distribution of electricity to sockets, lights, and appliances.

Commercial Buildings: In offices, shops, and other commercial spaces, they handle more complex electrical systems, including those for lighting, air conditioning, and computer networks.

Industrial Facilities: Factories and other industrial settings require robust distribution boards to manage high-power machinery and equipment.

Data Centers: These facilities rely on distribution boards to ensure a stable and continuous supply of power to sensitive electronic equipment.

Public Infrastructure: Distribution boards are also used in street lighting, traffic signals, and other public electrical systems.

Regular maintenance of distribution board cabinets is crucial for their longevity and safety. This includes:

Visual Inspections: Checking for signs of wear, damage, or corrosion.

Testing: Periodic testing of circuit breakers and other protective devices to ensure they are functioning correctly.

Cleaning: Dust and debris can accumulate over time, potentially causing short circuits or other issues.

Replacement: Components such as fuses and circuit breakers may need to be replaced as they wear out or after a fault.

Troubleshooting: Identifying and resolving issues such as tripped breakers or faulty circuits.

Innovations such as smart grid technology and integrated monitoring systems are enhancing their functionality, allowing for remote management and real-time diagnostics. This not only improves efficiency but also enhances safety by allowing for the early detection of potential issues.

Distribution board cabinets are a critical component of any electrical system, providing a centralized and organized means of managing electrical power. Their design, application, and maintenance are all essential aspects that contribute to the safe and efficient operation of electrical systems.

English

English русский

русский عربى

عربى