When it comes to high-voltage switchgear, fixed high-voltage switchgear, and high- and low-voltage distribution cabinets, safety is a critical concern. These components are essential for controlling and distributing electrical power, and their proper selection, installation, and maintenance are crucial for ensuring the safety and reliability of electrical systems.

Selecting a reputable supplier is the first step in ensuring the quality and reliability of high and low-voltage distribution cabinets. Different suppliers offer a variety of products with differing specifications and price ranges. It's important to evaluate suppliers based on their reputation, the quality of their products, and their ability to provide the specific types of distribution cabinets suited to your needs.

The primary function of high and low-voltage distribution cabinets is to manage and control voltage levels, which is essential for the safe operation of electrical systems. The cabinets should be designed to handle the specific voltage and current requirements of the devices they support. When evaluating safety, consider the following aspects:

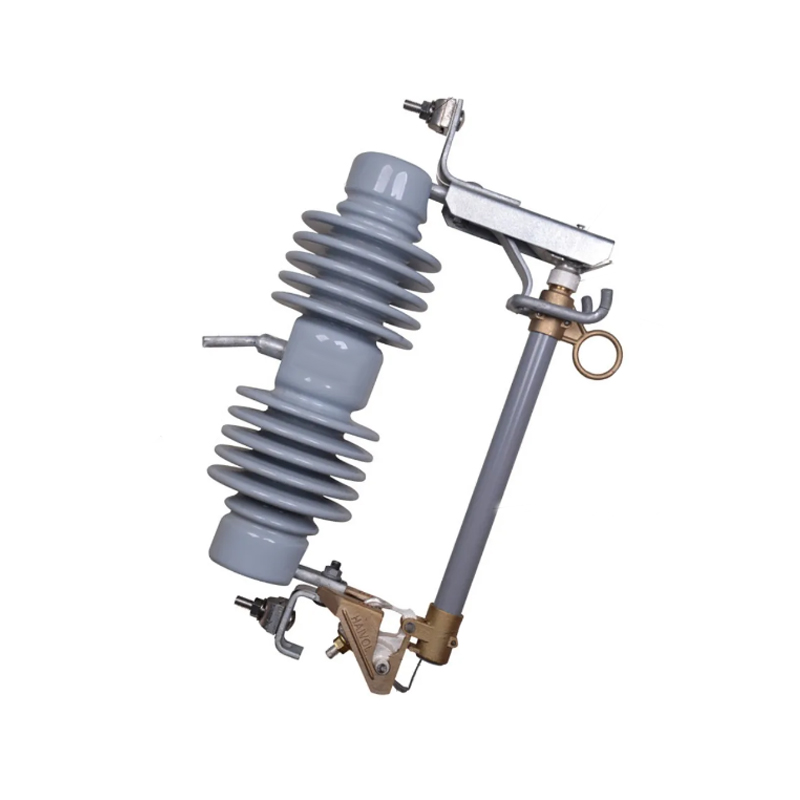

Insulation and Isolation: Ensure that the distribution cabinets have adequate insulation and isolation mechanisms to prevent electrical faults and accidental contact with live parts.

Protective Devices: The cabinets should be equipped with reliable circuit breakers, fuses, and surge protectors to guard against overloads, short circuits, and voltage spikes.

Quality Standards: Check that the distribution cabinets comply with relevant industry standards and certifications, such as IEC, ANSI, or local regulatory requirements. This compliance indicates that the products have been tested and verified for safety and performance.

Proper installation is crucial for the safe and effective operation of high and low-voltage distribution cabinets. Due to their complexity and the potential hazards involved, it is highly recommended to use professional installation services. Professional installers have the necessary expertise to ensure that the cabinets are installed correctly, securely, and in compliance with safety standards. They can also provide valuable guidance on the good placement and configuration of the cabinets to enhance safety and accessibility.

High and low-voltage distribution cabinets come in various types and configurations, each designed to meet specific needs. Some common types include MNS, DOMINO, and YDS, each offering different functionalities and features. When selecting distribution cabinets, consider the following:

Compatibility: Ensure that the cabinet is compatible with the existing electrical infrastructure and equipment.

Scalability: Look for cabinets that can be easily expanded or upgraded to accommodate future growth or changes in electrical demand.

Advanced Features: Modern distribution cabinets may include features such as remote monitoring, automated controls, and enhanced protection mechanisms. These advanced features can improve the overall performance and safety of the electrical system.

Regular maintenance is essential to ensure the ongoing safety and reliability of high and low-voltage distribution cabinets. Maintenance tasks should include routine inspections, testing of protective devices, cleaning, and checking for signs of wear or damage. Proper maintenance helps identify potential issues before they lead to failures or safety hazards.

The environment in which distribution cabinets are installed can significantly impact their performance and safety. Factors such as temperature, humidity, dust, and corrosive elements should be considered when selecting and installing these cabinets. For example, in industrial environments where exposure to dust or chemicals is common, cabinets with robust sealing and protective coatings may be necessary. Additionally, ensuring proper ventilation and cooling can help prevent overheating and extend the lifespan of the cabinets.

English

English русский

русский عربى

عربى