A Truck DC RV Fused Battery Isolator is a pivotal component that enhances the performance, safety, and longevity of battery setups in trucks and RVs.

A Truck DC RV Fused Battery Isolator serves the essential function of managing the charging and discharging of multiple batteries in a vehicle. Typically, these systems consist of a primary starting battery and one or more auxiliary batteries. The isolator ensures that the primary battery, responsible for starting the engine, remains charged and is not drained by auxiliary loads such as lights, refrigerators, or other accessories.

The isolator allows the alternator to charge both the primary and auxiliary batteries simultaneously when the engine is running. When the engine is off, the isolator disconnects the auxiliary battery from the primary battery, preventing the auxiliary loads from draining the primary battery. The inclusion of a fuse in the isolator adds an extra layer of protection, safeguarding the electrical system from overcurrent and potential damage.

By ensuring that the primary battery is dedicated solely to starting the engine, a fused battery isolator prevents deep discharges that can significantly shorten battery life. This separation of duties allows both the starting and auxiliary batteries to operate within their good charge and discharge cycles, extending their overall lifespan.

The isolator ensures that the primary battery is always ready to start the engine, even after extended periods of using auxiliary loads. This reliability is particularly important for RVs and trucks that may spend long durations at campsites or work sites where auxiliary power consumption is high.

The fuse integrated into the battery isolator provides critical protection against electrical faults. In the event of a short circuit or overcurrent condition, the fuse will blow, isolating the faulty circuit and preventing potential damage to the vehicle's electrical system or fire hazards.

For RV owners, a fused battery isolator allows for the use of electrical appliances and accessories without the fear of depleting the starting battery. This convenience translates to a more comfortable and enjoyable experience, whether on the road or parked at a campsite.

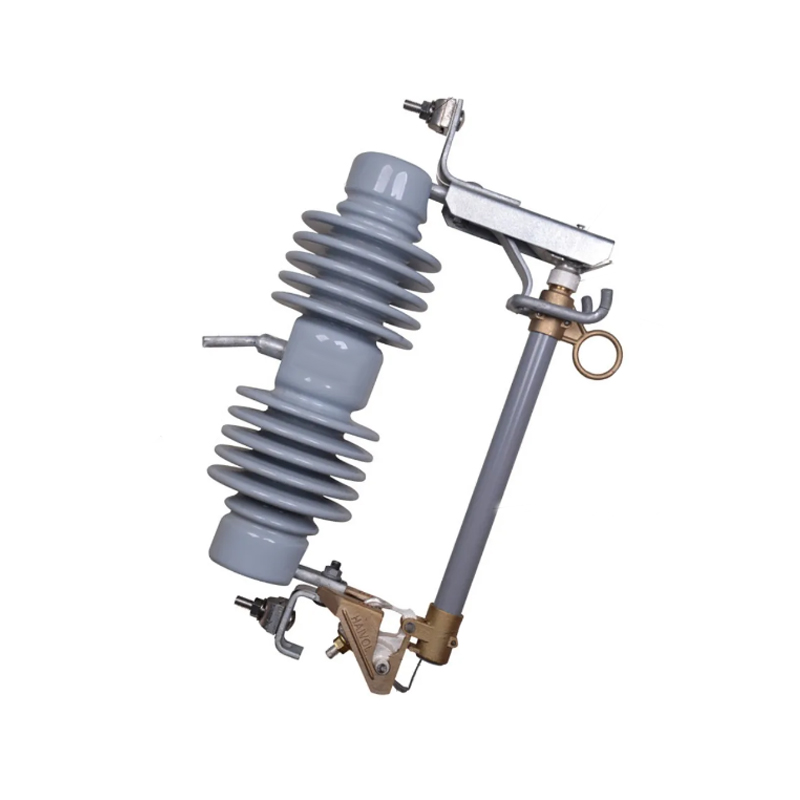

Before installation, it is essential to gather all necessary tools and components, including the battery isolator, fuses, wiring, connectors, and mounting hardware. Ensure that the isolator's specifications match the vehicle's electrical system requirements.

Choose a suitable location for mounting the isolator, preferably close to the batteries and away from excessive heat or vibration. Secure the isolator using the provided mounting hardware.

Primary Battery Connection: Connect the positive terminal of the primary battery to the corresponding terminal on the isolator.

Auxiliary Battery Connection: Connect the positive terminal of the auxiliary battery to the designated terminal on the isolator.

Alternator Connection: Connect the alternator's output to the input terminal on the isolator.

Ground Connection: Ensure that the isolator is properly grounded to the vehicle chassis to complete the electrical circuit.

Install the appropriate fuses in line with the positive connections to protect against overcurrent. The fuse rating should be selected based on the big current expected in the circuit.

After completing the installation, test the system to ensure proper operation. Start the engine and verify that both batteries are charging. Turn off the engine and check that the auxiliary battery is isolated from the primary battery.

Periodically inspect the isolator and associated wiring for signs of wear, corrosion, or damage. Ensure that all connections are tight and secure.

Check the fuses regularly and replace them if they are blown. Using the correct fuse rating is crucial for maintaining the protection of the electrical system.

Monitor the health and charge levels of both the primary and auxiliary batteries. Regularly check the electrolyte levels in lead-acid batteries and ensure that they are kept within the recommended range.

English

English русский

русский عربى

عربى