OEM/ODM Wholesale Vacuum Circuit Breaker Manufacturer Factory

Electrical systems are the backbone of modern infrastructure, powering everything from residential homes to industrial complexes. Ensuring the safety and reliability of these systems is paramount, and vacuum circuit breakers play a crucial role in achieving this. These devices are designed to protect electrical circuits from damage due to overcurrent conditions, such as short circuits or overloads.

A vacuum circuit breaker (VCB) is an electrical switch designed to interrupt current flow under normal or abnormal conditions. Unlike traditional air or oil-filled circuit breakers, VCBs utilize a vacuum as the insulating and arc-quenching medium. This choice of medium offers several advantages, including reduced maintenance, enhanced safety, and improved environmental friendliness.

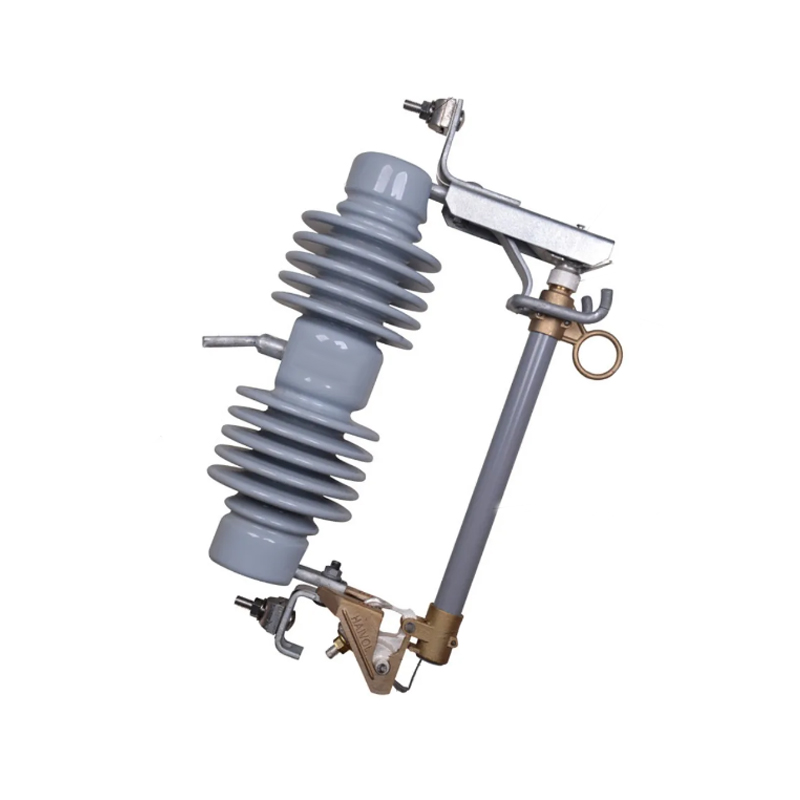

Components of a Vacuum Circuit Breaker

1. Vacuum Chamber: The heart of a VCB is the vacuum chamber, which houses the contacts. The vacuum provides insulation and arc-quenching properties.

2. Contacts: These are the conductive parts that touch to close the circuit and separate to interrupt the current. They are made of materials with high electrical conductivity and arc resistance.

3. Actuator: This component is responsible for the mechanical operation of the breaker, opening and closing the contacts. It can be manual, spring, or motor-operated.

4. Arc Chute: In the event of a fault, the arc chute helps to cool and extinguish the arc by rapidly dissipating its energy.

5. Interlocking Mechanism: This ensures that the breaker cannot be closed if the contacts are not in the correct position, adding an extra layer of safety.

6. Auxiliary Switches: These switches provide signals for control and monitoring purposes, indicating the status of the breaker.

The operation of a VCB can be broken down into three main stages:

1. Closing Operation: The actuator moves the contacts towards each other, closing the circuit and allowing current to flow.

2. Normal Operation: The contacts remain closed, and the vacuum environment ensures small electrical arcing and heat generation.

3. Interruption Operation: When a fault is detected, the actuator rapidly separates the contacts. The vacuum environment quickly extinguishes any arc that forms, preventing damage to the contacts and the surrounding equipment.

Advantages of Vacuum Circuit Breakers

1. Low Maintenance: The absence of consumable materials like oil or air means that VCBs require small maintenance.

2. High Reliability: The vacuum environment provides consistent performance, even in adverse conditions.

3. Long Lifespan: The robust design and materials used in VCBs contribute to their long operational life.

4. Environmental Compatibility: VCBs do not use harmful substances, making them an eco-friendly choice.

5. Compact Size: Due to the high dielectric strength of vacuum, VCBs can be smaller and lighter than their air or oil counterparts.

VCBs are used in a wide range of applications due to their versatility and reliability:

1. Power Distribution: In substations and power distribution centers, VCBs protect the grid from faults.

2. Industrial Applications: Factories and industrial plants rely on VCBs to safeguard their electrical systems.

3. Residential and Commercial Buildings: VCBs are used in building management systems to ensure the safety and continuity of power supply.

4. Renewable Energy Systems: Solar and wind farms use VCBs to protect their electrical infrastructure.

5. Transportation Systems: Railways and electric vehicle charging stations utilize VCBs for their high reliability and safety.

Vacuum circuit breakers are a testament to the evolution of electrical protection technology. Their unique combination of reliability, safety, and environmental benefits positions them as a preferred choice for various applications.

Understanding the components and operation of vacuum circuit breakers is crucial for engineers and technicians who work with these devices. Their ability to protect electrical systems from damage makes them an indispensable part of modern electrical infrastructure.

English

English русский

русский عربى

عربى