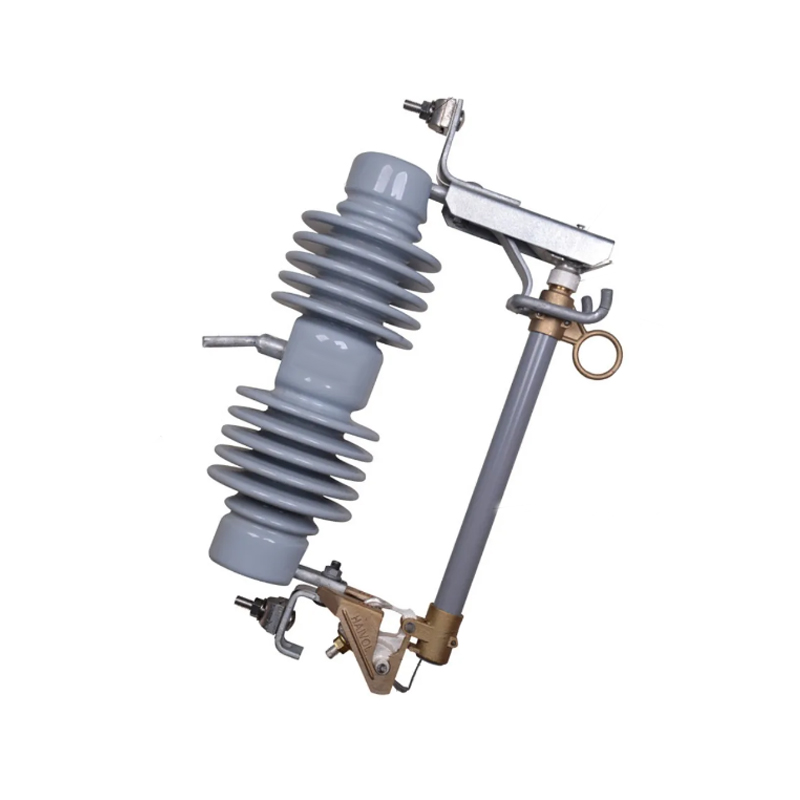

OEM Vacuum Circuit Breaker Wholesaler Exporter Producer

In the realm of electrical engineering, the safety and integrity of power distribution systems are of utmore importance. Vacuum circuit breakers stand as a testament to the innovation and advancement in electrical protection technology. These devices are engineered to interrupt or connect electrical circuits under normal or abnormal conditions, ensuring the continuity and safety of the electrical grid.

Vacuum circuit breakers operate on the principle of utilizing a vacuum as the insulating and arc-quenching medium. The vacuum environment within the breaker provides several advantages over other types of circuit breakers, such as those filled with air, oil, or sulfur hexafluoride (SF6).

1. Arc Extinguishing: When a circuit breaker interrupts a current, an arc is generated. In a vacuum, the arc is extinguished rapidly due to the absence of particles that would otherwise sustain the arc.

2. Contact Material: The contacts used in vacuum circuit breakers are typically made from copper or copper-chrome alloys, which have high electrical conductivity and can withstand the high temperatures generated during arcing.

3. Operation Mechanism: The operation of a vacuum circuit breaker involves a mechanism that separates the contacts within the vacuum chamber when a fault is detected. The rapid separation and the vacuum environment work together to extinguish the arc effectively.

Types of Vacuum Circuit Breakers

1. Outdoor Vacuum Circuit Breakers: Designed for outdoor applications, these breakers are built to withstand various weather conditions and are often used in substations.

2. Indoor Vacuum Circuit Breakers: These are used in indoor environments such as control rooms and switchboards, where space is often at a premium.

3. High-Voltage Vacuum Circuit Breakers: Capable of handling high voltages, these breakers are essential in transmission systems and large industrial applications.

Advantages of Vacuum Circuit Breakers

1. Environmental Sustainability: Unlike oil-filled breakers, vacuum breakers do not pose a risk of oil leakage, making them environmentally friendly.

2. Low Maintenance: The absence of consumable materials like oil or air reduces the need for regular maintenance, pilot to lower operational costs.

3. Reliability: The vacuum environment ensures consistent performance and reliability, even in harsh conditions.

4. Compact Design: Vacuum circuit breakers are typically smaller and lighter than their oil-filled counterparts, making them easier to install and integrate into existing systems.

Applications of Vacuum Circuit Breakers

1. Power Distribution: In both residential and commercial power distribution systems, vacuum breakers provide reliable protection against electrical faults.

2. Industrial Automation: In automated systems, vacuum breakers offer precise control and protection for sensitive equipment.

3. Renewable Energy Systems: With the rise of renewable energy, vacuum circuit breakers play a role in managing intermittent and variable power output from sources like solar and wind.

4. Electrical Grids: Modern electrical grids rely on vacuum breakers to manage load fluctuations and protect against faults in transmission lines.

Vacuum circuit breakers represent a significant leap forward in electrical protection technology. Their ability to extinguish arcs quickly and reliably, coupled with their compact design and low maintenance requirements, make them an ideal choice for a wide range of applications. As the demand for electrical power continues to grow and evolve, the role of vacuum circuit breakers in ensuring the safety and efficiency of our electrical systems becomes ever more critical. With ongoing advancements in materials and design, the future of vacuum circuit breakers looks bright, promising even greater performance and capabilities.

English

English русский

русский عربى

عربى