Switchgear panels, both low voltage (LV) and medium voltage (MV) play a crucial role in the distribution and management of electrical power across various industries. These panels are essential for ensuring the safe and efficient operation of electrical systems, from small commercial buildings to large industrial complexes.

Low voltage switchgear is primarily used in applications where the electrical voltage does not exceed 1,000 volts. It is widely employed in residential, commercial, and industrial settings to control, protect, and isolate electrical equipment. Some of the key applications include:

Residential Buildings: In residential settings, LV switchgear ensures the safe distribution of electricity throughout the home. It protects against overloads, short circuits, and ground faults, thereby safeguarding residents and electrical appliances.

Commercial Buildings: Office buildings, shopping malls, and hospitals rely on LV switchgear for distributing power to various systems such as lighting, HVAC, and elevators. The switchgear ensures continuous and reliable power supply, which is critical for the smooth operation of these facilities.

Industrial Facilities: In industrial environments, LV switchgear is used to manage power distribution to machinery, motors, and other heavy equipment. It is crucial for maintaining operational efficiency and safety in manufacturing plants, refineries, and other industrial sites.

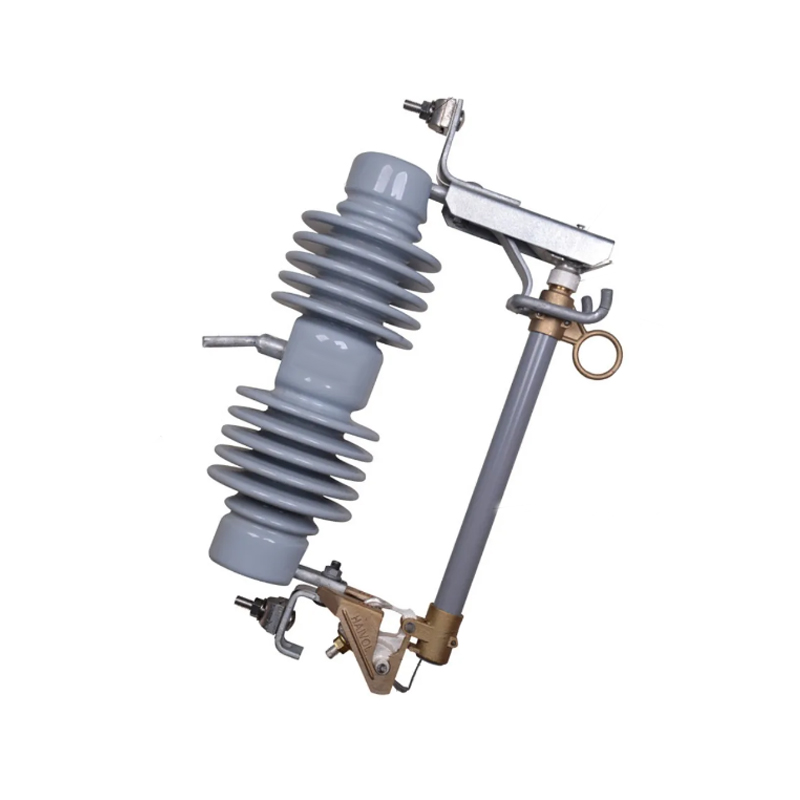

Medium voltage switchgear operates at voltages ranging from 1,000 to 35,000 volts. It is designed for use in applications where higher power levels are required. Key applications include:

Utilities: Electric utilities use MV switchgear for the distribution and control of electrical power across the grid. It plays a vital role in substations, where it helps manage the flow of electricity from power plants to consumers.

Renewable Energy: With the growing emphasis on renewable energy sources, MV switchgear is increasingly used in wind farms and solar power plants. It facilitates the integration of renewable energy into the grid, ensuring stable and reliable power supply.

Large Industrial Complexes: Factories, mines, and other large industrial facilities use MV switchgear to distribute power to various sections of their operations. It ensures the safe and efficient operation of high-power machinery and equipment.

The advancements in LV and MV switchgear technology have led to numerous benefits, enhancing safety, efficiency, and reliability in power distribution systems. Some of the notable benefits include:

Enhanced Safety: Modern switchgear is designed with advanced protective features such as arc flash detection, circuit breakers, and fault indicators. These features help prevent electrical accidents and ensure the safety of personnel and equipment.

Improved Efficiency: The integration of smart technology and automation in switchgear systems has significantly improved operational efficiency. Automated systems can monitor and control electrical loads in real-time, optimizing power usage and reducing energy waste.

Reliability and Durability: Contemporary switchgear is built to withstand harsh environmental conditions and heavy usage. The use of high-quality materials and advanced manufacturing processes ensures long-term reliability and small maintenance requirements.

The switchgear industry has witnessed significant technological advancements in recent years, driven by the need for smarter, more efficient, and environmentally friendly solutions. Some of the latest innovations include:

Smart Switchgear: The integration of Internet of Things (IoT) technology has given rise to smart switchgear systems. These systems can communicate with other devices and systems, providing real-time data on power usage, system health, and potential faults. This enables predictive maintenance and reduces downtime.

Eco-friendly Designs: Environmental concerns have led to the development of eco-friendly switchgear solutions. Manufacturers are now focusing on reducing the use of hazardous materials and increasing the recyclability of switchgear components. Additionally, there is a push towards using gases with lower global warming potential as insulating mediums.

Compact and Modular Designs: Space constraints in modern buildings and industrial facilities have led to the development of compact and modular switchgear designs. These designs not only save space but also allow for easier installation and scalability.

English

English русский

русский عربى

عربى