Electrical power systems are the backbone of modern society, providing the energy necessary for a wide range of applications, from residential to industrial. However, these systems are vulnerable to various threats, one of the more significant being lightning strikes. Lightning surges can cause severe damage to electrical equipment, pilot to costly repairs and service interruptions. To mitigate this risk, lightning surge arresters are employed, particularly in single phase power substations.

Lightning is a natural phenomenon that can generate badly high voltages and currents. When a lightning strike occurs near or directly hits an electrical system, it can induce voltage surges that far exceed the system's normal operating levels. These surges can travel through the electrical infrastructure, damaging transformers, circuit breakers, and other sensitive equipment. The effects of a lightning surge can be catastrophic, pilot to power outages, equipment failure, and even safety hazards.

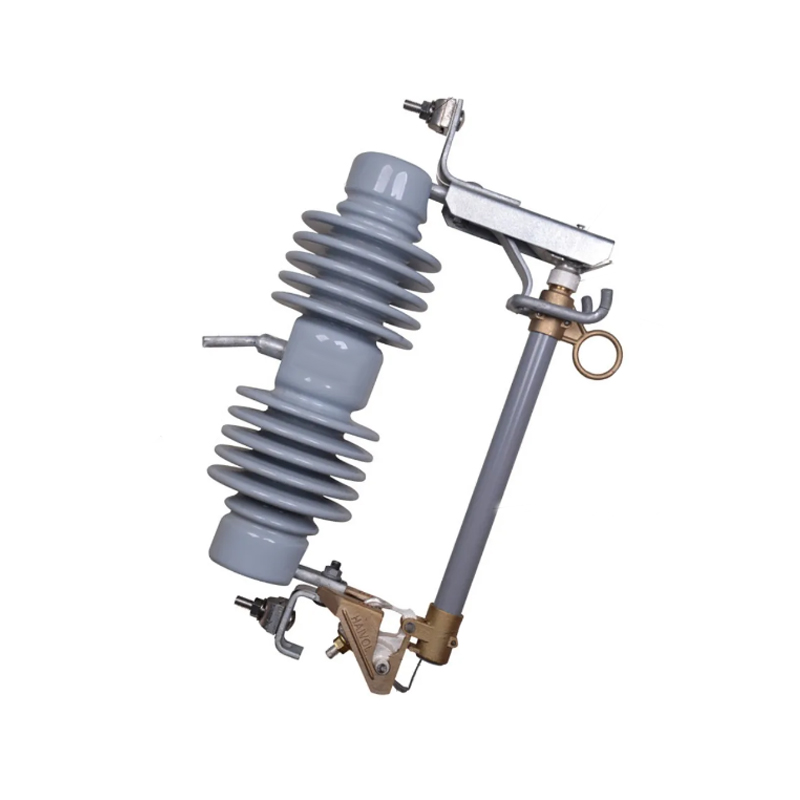

Surge arresters are devices designed to protect electrical systems from voltage surges caused by lightning and other transient events. They are connected in parallel to the equipment they are intended to protect. Under normal operating conditions, the arrester remains inactive. However, when a surge occurs, the arrester becomes conductive, allowing the surge to bypass the protected equipment and safely dissipate into the ground. Once the surge has passed, the arrester returns to its non-conductive state.

There are several types of lightning surge arresters, each with its own characteristics and applications:

Metal Oxide Varistors are the more common type of surge arrester used in power systems. They are made from a ceramic material that contains metal oxides. MOVs have a non-linear voltage-current characteristic, which allows them to remain non-conductive at normal operating voltages but becomes conductive when subjected to a surge.

Historically, silicon carbide arresters were widely used due to their ability to withstand high voltages and currents. They are made from a series of silicon carbide discs, which are excellent insulators and heat conductors. However, they have largely been replaced by MOVs due to their size, weight, and environmental concerns related to the manufacturing process.

These arresters combine the properties of silicon carbide with a small air gap to provide a controlled breakdown voltage. They are used in applications where a specific surge protection level is required.

Spark gaps are the simplest form of surge arrester, consisting of two electrodes separated by an air gap. They operate by creating a spark across the gap when the voltage reaches a certain level. While effective, they are less common in modern power systems due to their mechanical nature and the need for regular maintenance.

Single phase power substations are critical nodes in the electrical grid, often serving as the interface between high voltage transmission lines and lower voltage distribution networks. The protection of these substations from lightning surges is paramount to maintaining the reliability and continuity of the power supply.

When installing surge arresters in a single phase power substation, several factors must be considered:

Location: Arresters should be installed as close as possible to the equipment they are protecting to small the path length for the surge.

Coordination: The arresters must be coordinated with other protective devices, such as fuses and circuit breakers, to ensure that they operate effectively together.

Environment: The arresters should be selected and installed to withstand the environmental conditions of the substation, including temperature, humidity, and pollution levels.

Regular maintenance and testing are essential to ensure the continued effectiveness of surge arresters. This includes:

Visual Inspection: Regularly checking for signs of physical damage or deterioration.

Continuity Testing: Periodically testing the arrester's ability to conduct current during a surge.

Leakage Current Measurement: Monitoring the small current that flows through an arrester under normal conditions, which can indicate degradation over time.

English

English русский

русский عربى

عربى